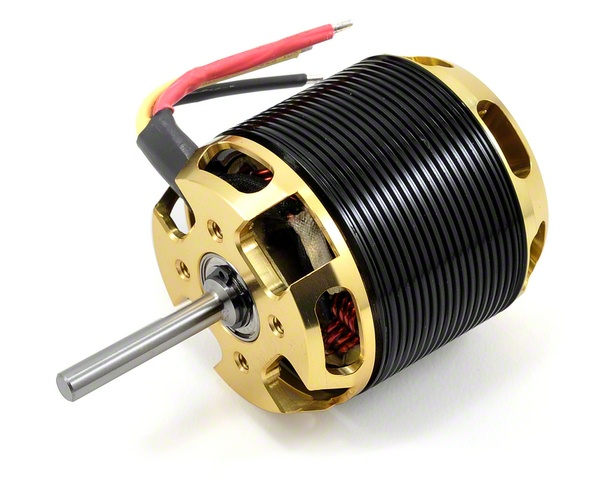

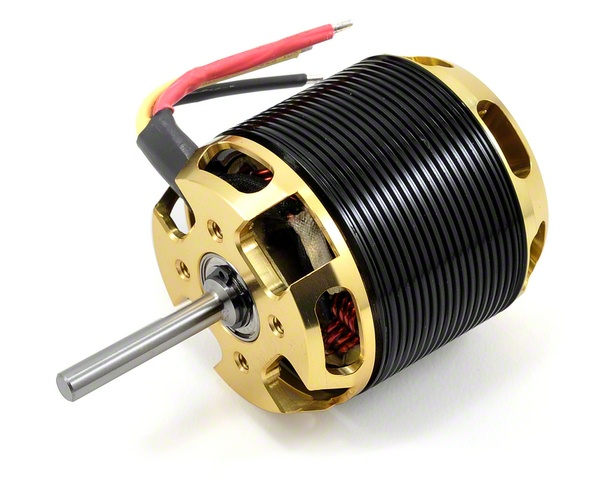

Scorpion HK-4530-540KV Ultimate!

- 700er Heli 12S Lipo

- 250A / 11000 Watt

Der Sorpion Scorpion HK-4530-540Kv Ultimate Motor nun in der Neuauflage als Ultimate Version. Der Motor wurde mit der neuartigen 1,5mm Draht Wicklung gefertigt. Diese Wicklungsart sorgt sogar für noch mehr Performance als die bisher herkömmliche Delta-Wicklung. Damit klettert der Scorpion HK-4530-540KV Ultimate auf den Leistungsolymp im 700er Helibereich. 4800 Watt / 115A Dauerleistung und SPitzen von 250A / 11000 Watt sind mit diesem Motor gar kein Problem.

Technische Daten:

- Stator Durchmesser: 45 mm (1.77 in)

- Stator Stärke: 30 mm (1.18 in)

- Stator Arme: 12

- Pole: 10

- Windungen: 9 Turn Wye

- Draht: 1-Strand 1.5 mm

- U/min/V: 540KV RPM/Volt

- Leerlauf(Io/10V): 2,11A

- Widerstand(RM): 0.010Ohm

- Dauerleistung: 115A / 4800 Watt

- Max. Leistung: 250A / 11000W (2 sec.)

- Gewicht: 565g

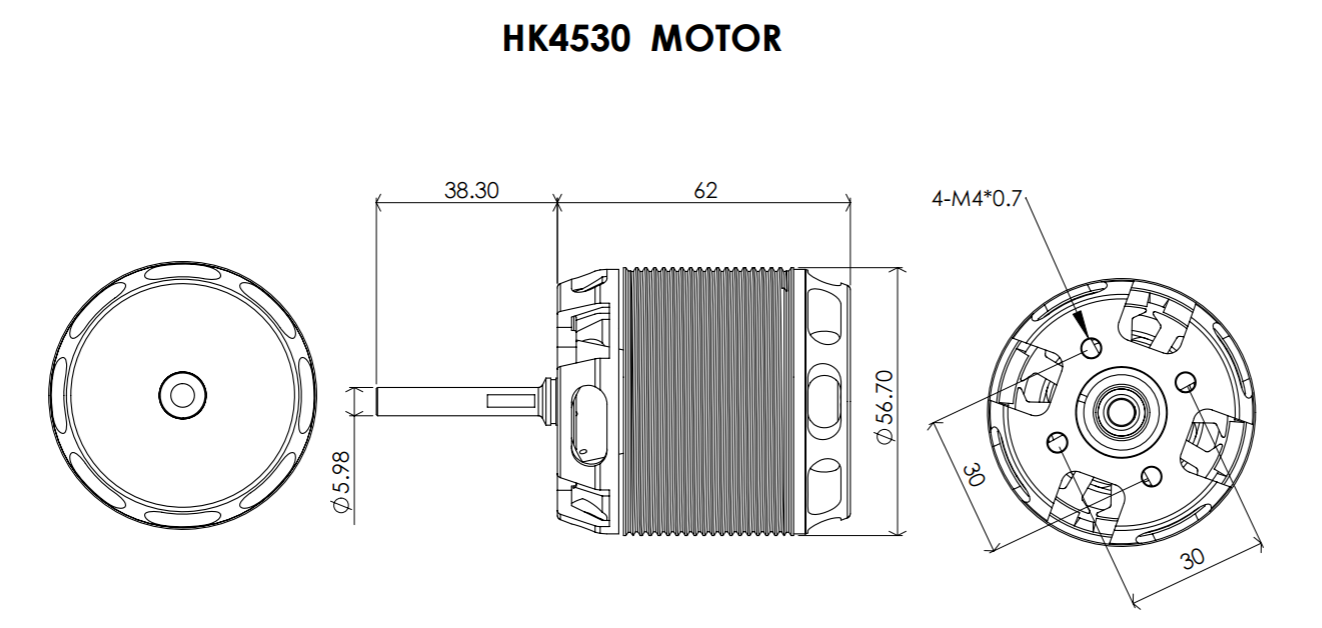

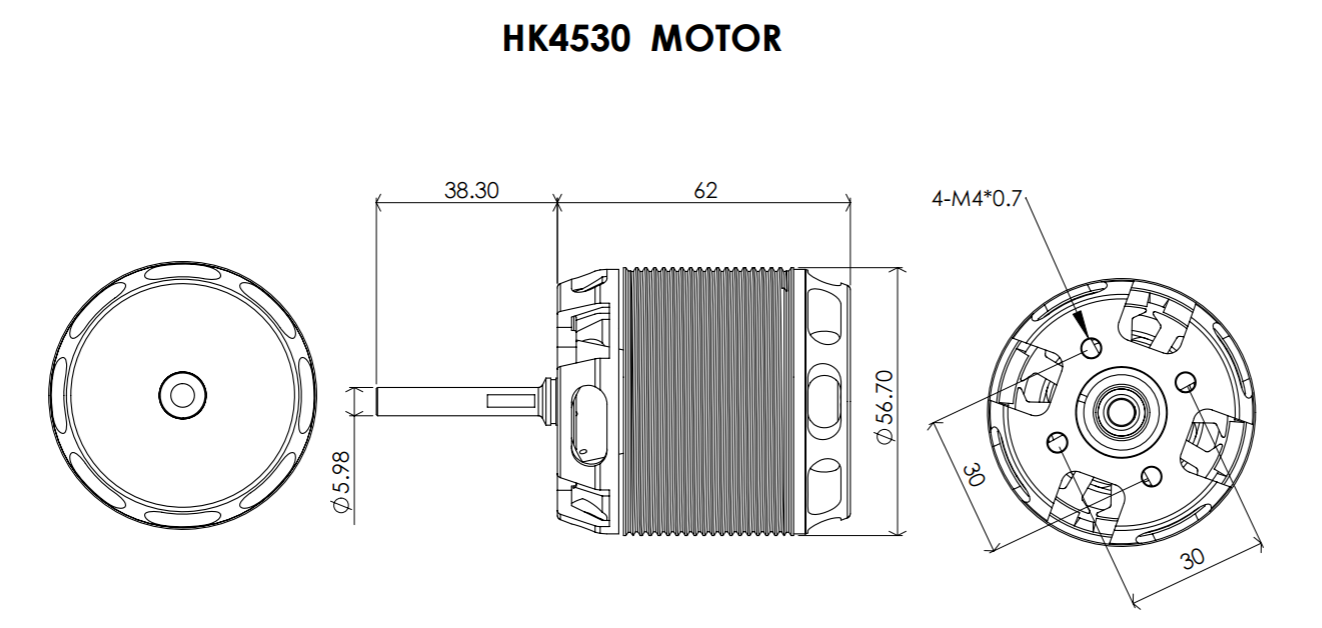

- Durchmesser: 56,7mm

- Welle: 5,98mm

- Motorlänge: 60,6mm

- Wellenlänge: 100mm

- Max. Lipo Zellen: 12S

- Motor Timing: 5deg 15 deg

- Motor Frequenz: 8kHz

Scorpion HK-4530-540KV Brushless Motor Limited Edition

is specially designed for a use on 700 class helicopters running on 12-cell Li-Po power. This motor represents the most technologically advanced power source ever offered for a 700 class electric helicopter and also produces 20% more torque than the Scorpion popular HK4035 series motors and exceed 89% efficiency.

Each of the new HK-4530-540KV Limited Edition motor is wound with a single strand of 1.5mm wire for the highest possible efficiency. This motor is capable of running continuously at an input power of 4800 watts at 115 amps, and can handle peak inputs of 11000 watts and 250 amps for 2 seconds.

Specifications:

Stator Diameter: 45 mm (1.77 in)

Stator Thickness: 30 mm (1.18 in)

No. of Stator Arms: 12

No. of Stator Poles: 10

Motor Wind: 9 Turn Wye

Motor Wire: 1-Strand 1.5 mm

Motor Kv: 540KV RPM/Volt

No-Load Current (Io/10V): 2.11 Amps

Motor Resistance (RM): 0.010 Ohms

Max Continuous Current: 115 Amps

Max Continuous Power: 4800 Watts

Weight: 565 Grams (17.25 oz)

Outside Diameter: 56.7 mm (2.23 in)

Shaft Diameter: 5.98 mm (0.24 in)

Body Length: 60.6 mm (2.39 in)

Overall Shaft Length: 100.0 mm (3.94 in)

Max Lipo Cell: 12s

Max Peak Current: 250A (2 seconds)

Max Peak Power: 11000 Watts (2 seconds)

Motor Timing : 5deg to 15 deg

Drive Frequency: 8kHz

Scorpion Competition Series Brushless Motors are built from the best materials available, and are designed to provide both quality and performance at an affordable price. Scorpion starts with high quality aluminum alloy parts that are produced on the latest CNC milling machines. These parts are then gold Electro-Coated to provide a beautiful, long-lasting finish. The stators are made with 0.2mm laminations to give maximum efficiency, and minimum Eddy current losses. The stators are epoxy coated to prevent shorts, and are wound with wire that is rated at 180 degrees C (356 F). The magnets used in Scorpion Motors are custom manufactured to be able to withstand high temperatures, making a motor that is virtually impossible to burn up in normal use.

Scorpion Motors are built to last, and are backed with a 2-Year warranty against defects in materials or workmanship. However, due to the high RPM of these motors, and the fact that we cannot control the installation and setup, the bearings are not covered by the 2-Year warranty, nor is any subsequent damage caused to the motor by a bearing failure. Bearings are a normal wear item, and as such, need to be maintained and changed periodically. For maximum life, make sure that a sufficient gap is left between the pinion and main gear during motor installation to avoid binding, and put a small drop of oil on each bearing every 5-6 flights. It is the responsibility of the pilot to ensure that the bearings are maintained properly.

For the best overall combination of quality, performance, and value, use Scorpion Motors in your helicopter!